Ständige Unterstützung und Transparenz bei der Realisierung Deiner Projekte von Beginn an. – Das ist es, was wir Dir als Lösungspartner bieten.

Egal in welcher Phase Deines Projektes Du ein Thema an uns adressierst, unser Team garantiert Dir eine umfassende Betreuung und stets die passenden Antworten auf Deine Fragen.

Erfahre mehr über die Möglichkeiten unserer Zusammenarbeit und profitiere von umfangreichen Materialien rund um Dein Maschinenprojekt.

Die hochpräzisen Fertigungsanlagen der Häcker Automation sind alternativlos,

wenn es um die Automatisierung komplexer und vielschichtiger Prozesse geht.

Für jede Phase deines Prozesses steht ein perfekt zugeschnittenes Modell bereit.

Die offene und modulare Maschinenplattform ist das perfekte Rüstzeug, wenn es um die Realisierung deiner umfangreichen Prozesse geht.

Elektrische, mechanischen und Software-Schnittstellen, einfache Anbindung von Bearbeitungsköpfen und Modulen.

Mit dem optionalen Wagen-System der Maschine X3 kannst Du die Flexibilität und Vielseitigkeit nochmals erhöhen.

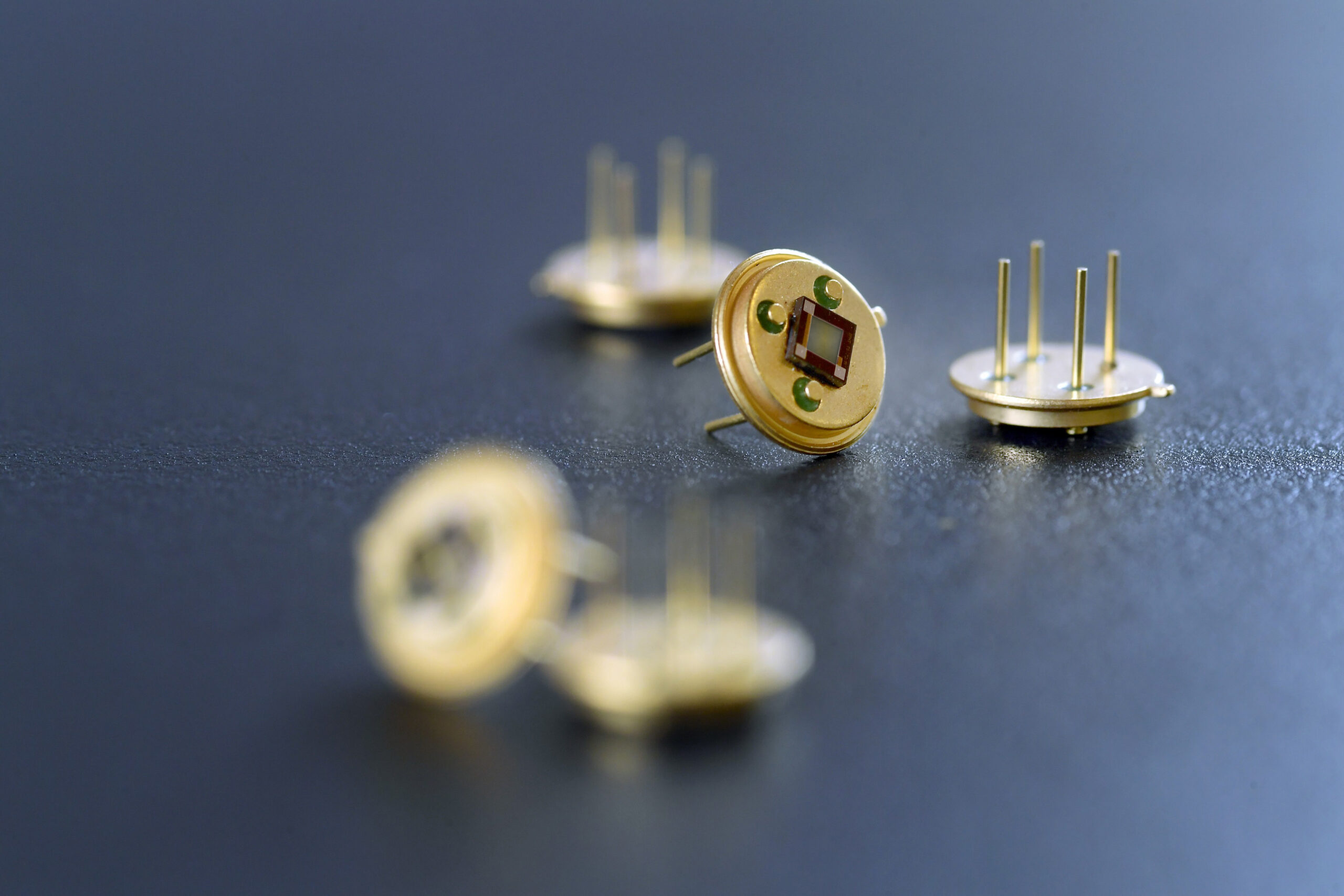

Die OurPlant Pocket ist eine Entwicklermaschine für den

perfekten Einstieg in die Mikromontage.

Die OurPlant D1 ist die Basis

für den nahtlosen Übergang

deiner Produkte in die Serienfertigung.

Der modulare Aufbau der OurPlant XTec garantiert die Anpassung an individuelle und sich schnell ändernde Prozessanforderungen.

Die OurPlant X3 kombiniert die hochgradig individuellen und

komplexen Prozesse

mit hoher Geschwindigkeit.

Um dir ein optimales Erlebnis zu bieten, verwenden wir Technologien wie Cookies, um Geräteinformationen zu speichern und/oder darauf zuzugreifen. Wenn du diesen Technologien zustimmst, können wir Daten wie das Surfverhalten oder eindeutige IDs auf dieser Website verarbeiten. Wenn du deine Zustimmung nicht erteilst oder zurückziehst, können bestimmte Merkmale und Funktionen beeinträchtigt werden.